Non Ferric Alum

20.00 INR/Kilograms

Product Details:

- Boiling point Not applicable (decomposes)

- Form Solid

- Ph Level 2.8 - 3.5 (1% solution)

- Taste Astringent

- Purity 98%

- HS Code 28332220

- Other Names Alum, Non Ferric Alum

- Click to view more

X

Non Ferric Alum Price And Quantity

- 20.00 INR/Kilograms

- 1 Kilograms

- Max 0.5%

- Minimum 17%

- Max 0.3%

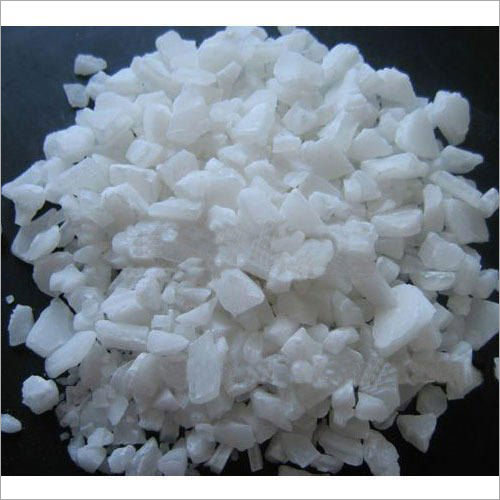

- White crystalline powder or lumps

- 25/50 kg HDPE bags with inner liner

- Maximum 0.005%

- 2.8 - 3.5

- 24 months

Non Ferric Alum Product Specifications

- 2.71 Gram per cubic centimeter(g/cm3)

- Al2(SO4)3

- Store in cool, dry place, tightly closed

- 233-135-0

- Odorless

- circa 92.5C (decomposes)

- Powder / Lumps

- 342.15 g/mol

- Yes

- Soluble in water

- Aluminium Sulphate

- 2.8 - 3.5 (1% solution)

- Astringent

- Industrial Grade

- 98%

- Not applicable (decomposes)

- Solid

- Coagulating agent

- Water treatment, paper industry, textile industry, dyes

- IS 260:2011

- Clarification and purification of water

- [Al2(SO4)3]

- 28332220

- Alum, Non Ferric Alum

- Max 0.5%

- Minimum 17%

- Max 0.3%

- White crystalline powder or lumps

- 25/50 kg HDPE bags with inner liner

- Maximum 0.005%

- 2.8 - 3.5

- 24 months

Non Ferric Alum Trade Information

- 10000 Kilograms Per Week

- 1 Week

- Packet

- All India

Product Description

Non Ferric Alum is the pure form of ammonium sulfate with no ferric ions present in the chemical composition. We manufacture this substance using aluminum trihydrate as the major raw ingredient. This material reacts with sulfuric acid under appropriate conditions to produce non-ferric alum. Once this Non Ferric Alum is produced and quality checked, it is packed by us using protective packaging material. To know more about this product feel free to ask, it will be our pleasure to assist you.

Specification :

| Physical State/Form | Solid |

| Usage | Industrial |

| Packaging Type | Bag |

| Packaging Size | 25/50 kg |

| Application | Water treatment |

High-Purity Aluminium Sulphate for Industrial Applications

Non Ferric Alum, with 98% purity and low iron content, delivers effective coagulation, making it ideal for water clarification and purification across a range of industries. Its solid, odorless, and astringent nature allows for versatile utilization in the paper and textile sectors, as well as in dye processes. The product is formulated to strict IS 260:2011 standards for reliability and performance.

Optimal Performance and Easy Handling

Available in white crystalline powder or lumps, Non Ferric Alum comes in 25/50 kg HDPE bags with inner liners to maintain quality. The substance offers a shelf life of 24 months if properly stored in a cool, dry, and tightly closed environment. Its high solubility in water and stable chemical properties assure consistent results throughout its shelf life.

FAQ's of Non Ferric Alum:

Q: How is Non Ferric Alum typically used in water treatment?

A: Non Ferric Alum acts as a coagulating agent in water treatment plants, helping to clarify and purify water by binding and removing suspended solids and particles, resulting in clearer, safer water.Q: What makes Non Ferric Alum different from Ferric Alum?

A: Non Ferric Alum contains virtually no iron (maximum 0.005%), giving it a white color and making it preferred for applications where iron contamination needs to be minimized, such as in paper and textile manufacturing.Q: When should Non Ferric Alum be applied during industrial processes?

A: Non Ferric Alum is usually introduced during the initial clarification or purification stages, whether in water treatment, the paper industry, or textile processing, to enhance removal of impurities before further processing.Q: Where can Non Ferric Alum be stored to preserve its quality?

A: It should be stored in a cool, dry place, tightly closed in its original HDPE packaging, to prevent moisture uptake and ensure product integrity throughout its 24-month shelf life.Q: What process ensures the high purity of Non Ferric Alum?

A: High purity is achieved by controlled production processes using premium raw materials, which are rigorously tested to limit iron and insoluble matter, aligning with IS 260:2011 standards.Q: What are the primary benefits of using Non Ferric Alum in industrial applications?

A: The main benefits include effective coagulation, increased clarity, low contamination risk due to minimal iron content, and dependable performance in water treatment, papermaking, and dyeing operations.Q: How should Non Ferric Alum be handled safely by dealers and distributors?

A: Personnel should avoid inhalation or contact with eyes and skin, and use protective gloves if necessary. Proper storage and handling as per instructions help maintain product safety and quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Non Ferric And Ferric Alum' category

"We deal in bulk inquiries only"

Get a Quote

Get a Quote

Call Me Free

Call Me Free